Sheet Metal Fabrication Services

Our Sheet Metal Fabrication Services provide precision-engineered, custom components through advanced techniques and a trusted global network.

Source Now

The 4 Main Steps of Sheet Metal Fabrication

Sheet metal fabrication transforms raw metal sheets into precise components through cutting, bending, and assembly.

-

1

Design & Programming

CAD models are converted into fabrication instructions for cutting, bending, and forming

-

2

Material Selection

The appropriate metal is chosen, cut to size, and prepared for fabrication.

-

3

Machining & Production

Processes like laser cutting, punching, bending, and welding shape the final component

-

4

Finishing

Parts undergo deburring, coating, painting, and final inspections to ensure precision and durability

What is Sheet Metal?

Sheet metal fabrication transforms flat metal sheets into precise components using cutting, bending, and forming techniques. It’s widely used in industries like automotive and aerospace due to its accuracy, cost-effectiveness, and compatibility with materials such as aluminum and steel

Key Techniques:

- Laser Cutting & Punching – Create intricate shapes with precision.

- Press Braking – Bend metal to exact angles for structural integrity.

- Stamping & Deep Drawing – Form complex, multi-dimensional parts efficiently.

This process is ideal for producing durable, high-quality parts, from prototypes to large-scale manufacturing.

Sheet Metal Applications

Sheet metal fabrication is a flexible manufacturing process used to create a wide range of metal components. It supports both high-volume production and low-volume, custom applications.

Common Sheet Metal Parts:

- Electrical Enclosures – Protect wiring and electronic systems.

- Electronics Parts – Precision components for hardware

- Chassis – Structural frames for various devices.

- Brackets & Mounts – Support and secure mechanical parts

- Appliances – Durable metal parts for household and industrial use.

Most Popular Processes

At SourceFlow, we connect you with trusted, top-tier machine shops, providing CNC machining services that span from basic drill presses to sophisticated 5-axis and 6-axis machining centers.

Popular finishes for metal work

The network works well for components that require a specialized color or material options

Standard (As-Milled)

Minimal post-processing or treatment on parts is done.

Bead Blast

The part surface is left with a smooth, matte appearance.

Anodized

arts can be anodized in different colors—clear, black, red, and gold are most common—and are usually associated with aluminum.

Chromate Conversion Coating

Provides corrosion resistance and good conductivity properties. Can be used as a base for paint.

Powder Coat

This process is where powdered paint is sprayed onto a part and baked in an oven. This creates a strong, wear- and corrosion-resistant, more durable layer than standard painting methods.

Electroless Nickel Plating

A sheet metal fabrication process that provides uniform nickel coating which offers protection from corrosion, oxidation, and wear on irregular surfaces.

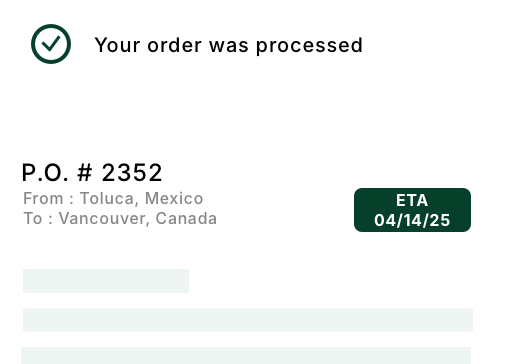

Turnkey Sourcing Solution

Discover how our end-to-end process simplifies supplier selection and procurement

Source now