Custom CNC Machining Services

Our CNC machining services utilize a carefully vetted global network to consistently deliver high-quality parts tailored to your specifications.

Source Now

The 4 main steps of CNC Machining

CNC machining is a versatile process that can be used to manufacture parts and components from a variety of materials, including metals, plastics, and aluminium

-

1

Design & Programming

CAD models are converted into CNC instructions.

-

2

Material Selection

The raw material is loaded and fixtures are set for precision machining

-

3

Machining & Production

The CNC machine operates based on programmed instructions.

-

4

Finishing

Parts undergo deburring, polishing, coating, and final quality inspections.

Who is CNC Machining for?

CNC machining is ideal for companies and industries that require high precision and accuracy in their manufacturing processes.

This includes industries such as aerospace, automotive, medical devices, electronics, and many more. It is also beneficial for companies that require custom-designed parts that cannot be produced using traditional manufacturing methods.

The benefits of CNC Machining

- Precision and accuracy which reduces the need for manual intervention

- Efficiency and speed – CNC machines can help reduce lead times

- Versatility: CNC machines can work with a wide range of materials and produce a variety of shapes and sizes

- Cost-effectiveness While initial setup costs for CNC machining may be higher, the technology offers long-term cost savings through increased efficiency

Most Popular Processes

At SourceFlow, we connect you with trusted, top-tier machine shops, providing CNC machining services that span from basic drill presses to sophisticated 5-axis and 6-axis machining centers.

Popular finishes for machining

The network works well for components that require a specialized color or material options

Standard (As-Milled)

The fastest turnaround finish. Machined parts retain visible tool marks and may have sharp edges or burrs, which can be removed upon request

Bead Blast

The part surface is left with a smooth, matte appearance.

Tumbled

A batch process using vibrating media to remove sharp edges and burrs from CNC parts. It can also smooth exterior surfaces by reducing machine marks

Anodized

arts can be anodized in different colors—clear, black, red, and gold are most common—and are usually associated with aluminum.

Titanium Anodize

Also called Tiodize, this finish increases fatigue strength and the wear resistance of a part. Titanium anodized parts are common in aerospace and medical device manufacturing.

PTFE Impregnated Hard Anodize

A hard coat anodizing process that embeds PTFE for a self-lubricating, dry-contact surface while maintaining Type III hard coat protection. Suitable for aluminum alloys and titanium

Chromate Conversion Coating

Provides corrosion resistance and good conductivity properties. Can be used as a base for paint.

Powder Coat

This process is where powdered paint is sprayed onto a part and baked in an oven. This creates a strong, wear- and corrosion-resistant, more durable layer than standard painting methods.

Electropolishing

An electrochemical process cleans steel parts to reduce corrosion and improve appearance

And many more

- Silver Plating

- Gold Plating

- Zinc Plating

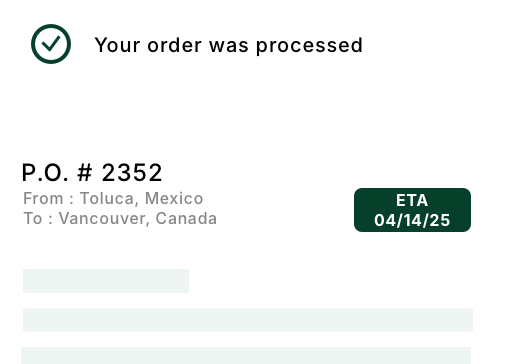

Turnkey Sourcing Solution

Discover how our end-to-end process simplifies supplier selection and procurement

Source now