AQL Sample Calculator

AQL Calculator Acceptable Quality Limit

Use our AQL sampling simulator to easily calculate the ideal sample size and acceptance numbers for your inspections. Try it now to streamline and optimize your sampling process!

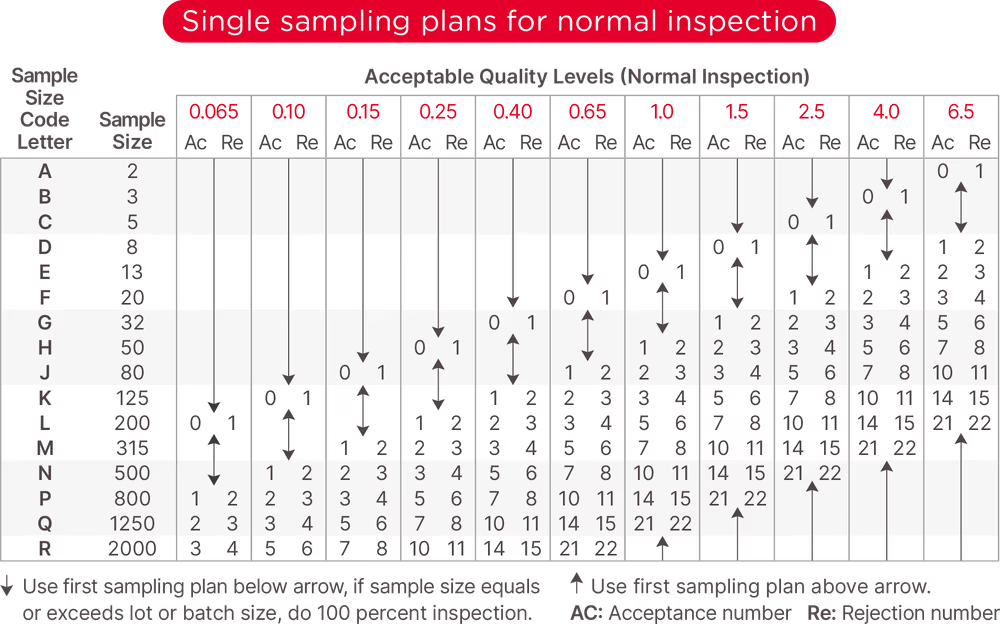

Understanding the AQL Tables

Understanding the two primary AQL tables—General Inspection Level and Special Inspection Level—is essential for accurately conducting product inspections. The General Inspection Level table is used for most routine quality control checks and helps determine the sample size and acceptable defect limits based on the lot size. It is divided into different levels of severity, allowing businesses to choose the most appropriate inspection plan based on the risk and importance of the product. On the other hand, the Special Inspection Level table is applied in cases where the quality of the product is critical, such as when dealing with high-stakes products or when extra scrutiny is required. It offers a more stringent sampling plan and sets lower acceptance limits for defects. By understanding these two AQL tables and selecting the right inspection level, businesses can ensure accurate assessments, reduce the chances of defects, and maintain high standards of product quality.

All Your Part Inspections, Verified

The Acceptance Quality Limit (AQL) is a crucial metric in product inspections, determining the maximum allowable number of defective items in a sample batch. If the number of defective items exceeds this threshold, the entire batch is rejected. AQL values vary depending on defect severity, with critical defects typically having an AQL of 0, as they are deemed unacceptable.

AQL is based on the ISO 2859 standard, which guides sampling inspections. This internationally recognized standard provides detailed tables to help determine the appropriate sample sizes and defect thresholds, ensuring accurate and reliable quality control.

At QIMA, our expert inspectors strictly follow AQL sampling plans, performing thorough evaluations of production samples to verify compliance with AQL standards. With our transparent, AQL-driven inspection process, you can confidently assess whether to accept or reject a batch, minimizing risk and ensuring consistent product quality.“

This version incorporates more keywords related to AQL, product inspection, and quality control, which can improve search visibility!

Benefits of using the AQL method

Using the AQL (Acceptance Quality Limit) methodology offers several key benefits for businesses looking to maintain high-quality standards in their products. AQL helps optimize inspection processes by defining clear thresholds for acceptable defect levels, ensuring that only batches meeting these criteria are approved. This results in improved product consistency and reduced risk of defective goods reaching customers. By adhering to the AQL method, companies can save on costs associated with unnecessary inspections while still ensuring compliance with international quality standards, such as ISO 2859. Additionally, AQL-driven sampling allows for efficient and reliable quality assessments, enabling businesses to make informed decisions on whether to accept or reject product batches, ultimately enhancing customer satisfaction and brand reputation.