World-class, Cost-Effective Plastic Injection Solutions

Our Plastic Injection Molding Services deliver high-quality, custom plastic components using advanced molding techniques and a reliable global network

Source Now

The 4 Main Steps of Plastic Injection

Plastic injection molding is a versatile manufacturing process used to produce precise and durable plastic components at scale

-

1

Design & Programming

CAD models are developed, and a precision mold is manufactured for injection molding

-

2

Material Selection

The right plastic resin is chosen, melted, and prepared for injection

-

3

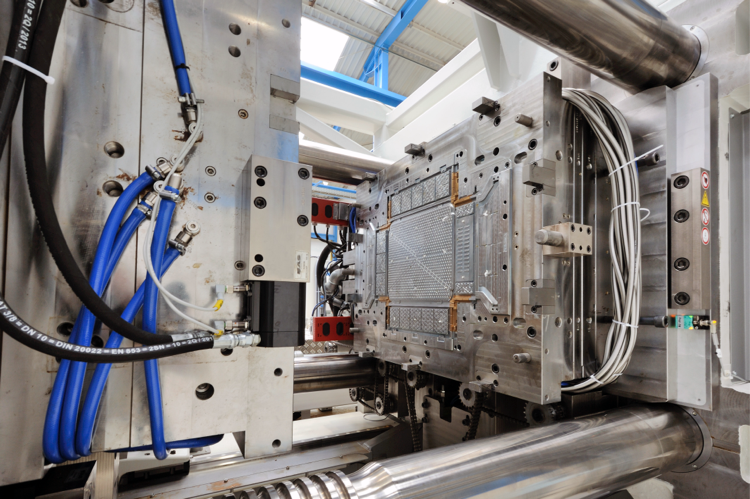

Mold Creation

A high-precision mold is manufactured from steel or aluminum, designed to shape the final product accurately

-

4

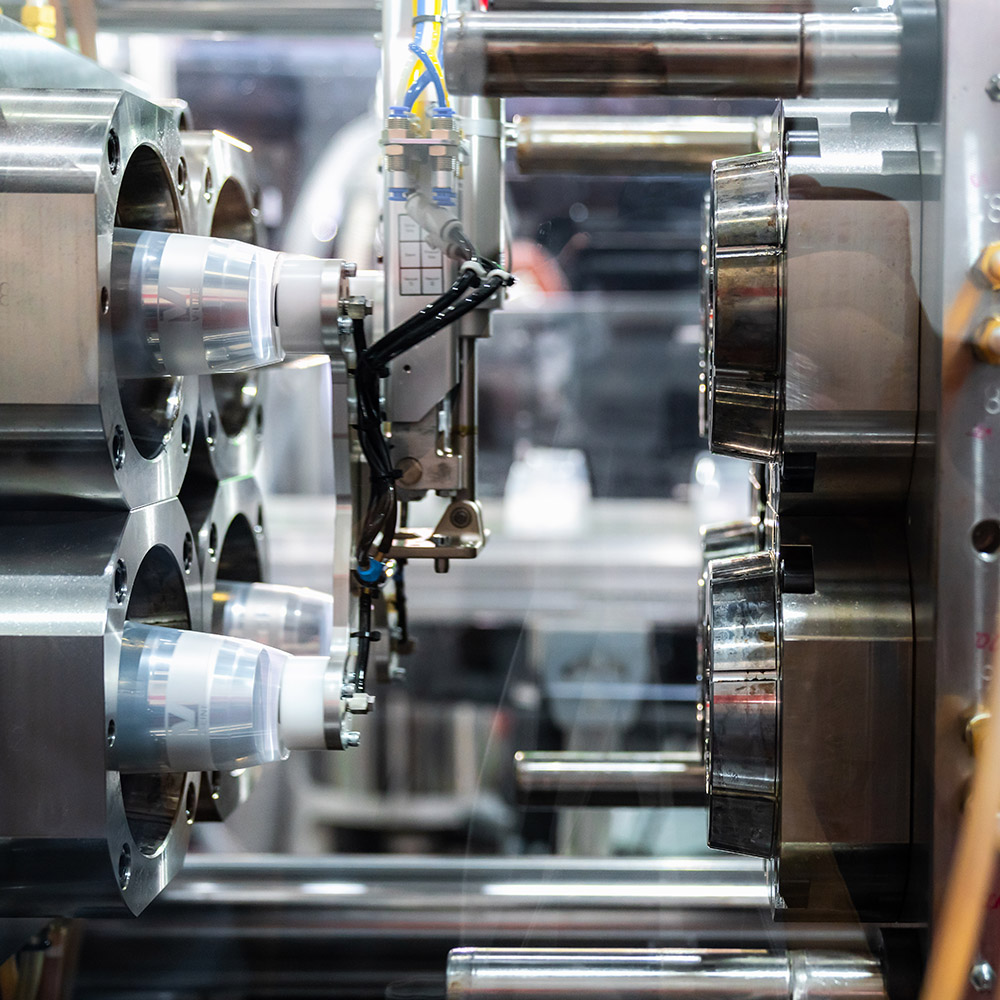

Injection & Molding

Molten plastic is injected into the mold cavity, cooled, and solidified into its final form, than surface treatments are applied

Popular finishes for Plastic parts

The network works well for components that require a specialized color or material options

Standard (As-Milled)

Minimal post-processing or treatment on parts is done.

SPI Finishes

standardized surface textures applied to molds, ensuring consistent part appearance and performance

Mold Texturing

Range of finishes including matte, swirls, lines, and patterns

Threaded Inserts

We can install most commonly used standard inserts in UNF and metric sizes.

Laser Engraving

Engrave part numbers, logos, and more onto your parts.

What is Plastic Injection

Injection molding is a manufacturing process used to produce precise, cost-efficient parts, primarily from plastics, at high volumes.

Molten material is injected into a custom-designed mold that shapes the part. Once the material cools and solidifies, the mold opens, and the finished part is ejected.

This process is ideal for creating intricate parts with tight tolerances, making it widely used in industries such as automotive, medical devices, and consumer goods.

Plastic Injection Applications

Plastic injection molding is widely used to produce high-precision parts across various industries.

The process is ideal for creating complex, durable components with tight tolerances. By injecting molten plastic into custom molds, it can produce parts in large volumes, ensuring consistency and cost efficiency.

Plastic injection is commonly used in applications such as automotive parts, medical devices, consumer electronics, packaging, and household products, making it a versatile solution for both functional and aesthetic components.

Turnkey Sourcing Solution

Discover how our end-to-end process simplifies supplier selection and procurement

Source now